Flammability

No

Chemical Formula

FeSi

melting point

1200°C - 1380°C

Boiling Point

2355°C

Volumetric mass

6.8 to 7.2

Color

Dark Gray

14

Si

Silicon

28.086

26

Fe

Ferrum

55.845

13

Al

Aluminum

26.982

20

Ca

Calsium

40.078

6

C

Carbon

12.011

15

P

Phosphorus

30.974

16

S

Sulfur

32.065

What is Ferrosilicon?

Ferrosilicon is a type of ferroalloy composed primarily of iron and silicon. It is used in various industries, including steelmaking and casting. Ferrosilicon can contain varying amounts of silicon (typically ranging from 15% to 90%) depending on the production method. It is usually produced by reducing silica with carbon materials and iron in an electric arc furnace.

Applications

Acts as an oxidizing agent in steelmaking and certain iron alloys.

Serves as an alloying agent to increase the silicon content in cast iron parts.

Functions as a grain refiner and improves the mechanical properties of cast iron.

Used as a raw material for producing other ferroalloys such as Ferrosilicon Magnesium and ferromolybdenum.

Used in electrode covers for electric arc welding.

Employed as a raw material for producing Magnesium ingots through the thermal regeneration method (Pidgeon process)

Laboratory Parameters

Ferrosilicon exhibits various physical and chemical properties that are contingent upon its composition, grain size, and method of production. Some of these properties include:

- Bulk Density: Approximately 6.8 g/cm³ to 7.2 g/cm³ depending on its specific composition.

- Melting Temperature: Ranges from 1200°C to 1380°C depending on the silicon content and impurities.

- Boiling Point: Around 2355°C for all types of Ferrosilicon.

- Color: Solid Ferrosilicon ranges in color from silver-gray to dark gray, depending on the silicon content and oxidation state.

- Combustibility: Combustible in the form of dust particles but stable in bulk or granular form.

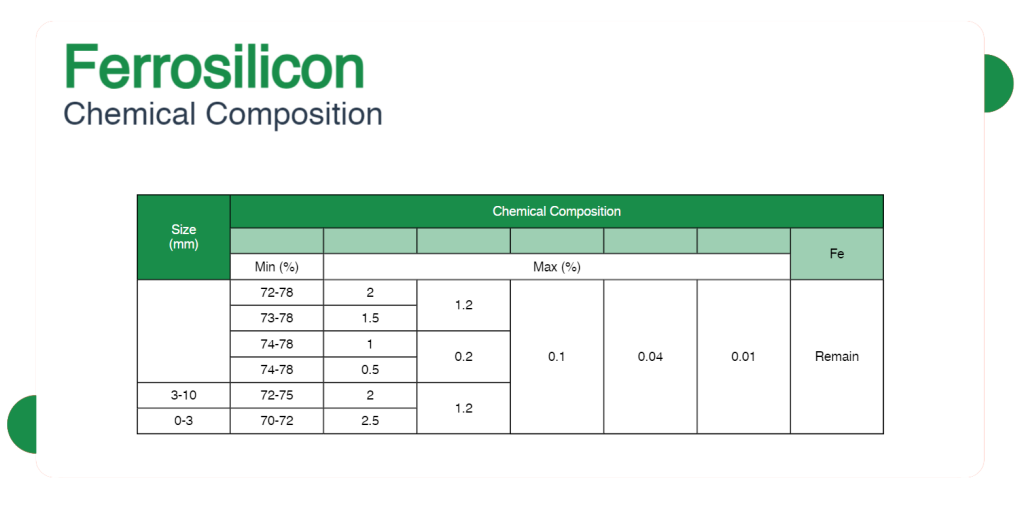

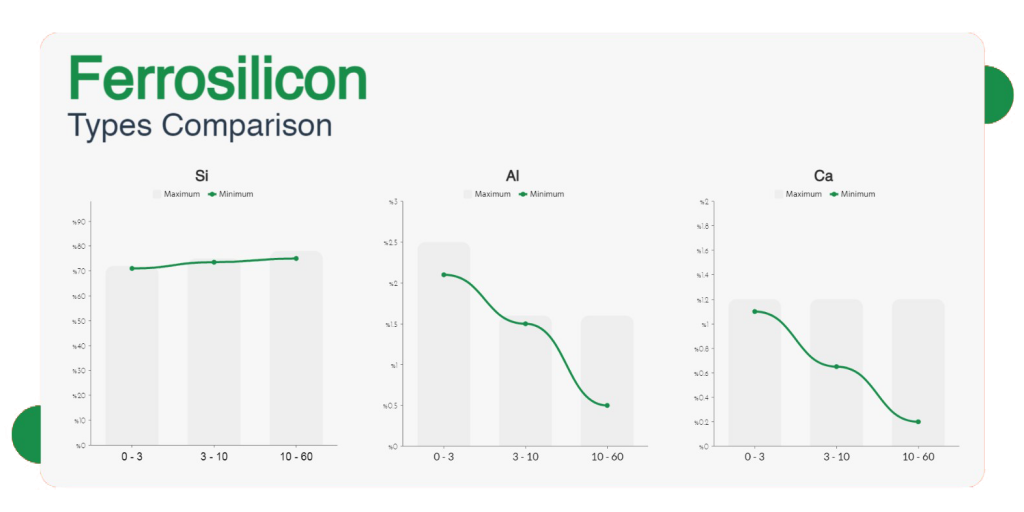

Granulation and Grades

Ferrosilicon can be categorized into different types based on the silicon and aluminum content, as well as grain size. The product manufactured by Iran Ferrosilice is available in three granulations: 0-3 mm, 3-10 mm, and 10-60 mm. The chemical characteristics of all three granulations are provided in the table below.

- Fine (0-3 mm)

- Medium (3-10 mm)

- Coarse (10-60 mm)

FeSi

Ferrosilicon 10-60 mm

FeSi

Ferrosilicon 3-10 mm

FeSi

Ferrosilicon 0-3 mm

Packages

produced Ferrosilicon by Iran’s ferrosilicon factory can be sold in the following two ways based on the type of granularity, volume and customer demands:

- Bulk

- Big Bag – 1000 Kg