Regardless of the actual value of the products, you see the potential of using related ferroalloys in this section.

All content on this page has been created by ChatGPT 4 AI

Ferrosilicon

Ferrosilicon’s versatility significantly influences the transportation industry, enhancing the strength, durability, and performance of materials and components. These enhancements contribute to improved safety, efficiency, and sustainability across transportation sectors.

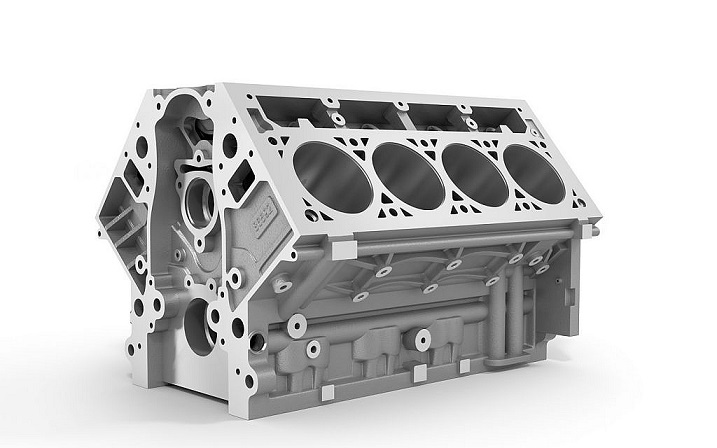

Automotive industry

Ferrosilicon usage in steel and cast iron alloy production strengthens and enhances various automobile components, including engine shells, chassis components, transmission gears, and suspension components, ensuring safer and more reliable vehicles.

Alloy production

Ferrosilicon is pivotal in producing high-strength and durable materials necessary for constructing transportation vehicles like cars, trains, ships, and airplanes.

Aerospace industry

Ferrosilicon-containing materials play a crucial role in aircraft part and engine manufacture, ensuring aircraft safety and performance.

Marine industry

In ship construction and maintenance, Ferrosilicon improves hull and critical component corrosion resistance, while also aiding in propeller, ballast material, and electrical system production.

Electric vehicle (EVs)

Ferrosilicon-based electrical steel enhances the efficiency and performance of electric vehicle motors and generators.

Lightweight materials

Ferrosilicon aids in the production of lightweight alloys, beneficial for reducing vehicle weight and improving fuel efficiency, particularly in automotive and aerospace applications.

Anti-corrosion coating

Ferrosilicon-based coatings protect transportation components against corrosion, extending their lifespan and reducing maintenance costs.

Railway industry

Ferrosilicon contributes to rail, wheel, and component strength and wear resistance, enhancing train comfort, safety, and reducing maintenance requirements.

Magnesium Ferrosilicon

Magnesium Ferrosilicon holds significant value in the transportation sector due to its ability to enhance the mechanical properties of materials, particularly in the production of ductile iron. This substance contributes to the strength, durability, and efficiency of components and materials used across various transportation methods.

Ferrosilicon Magnesium is an alloy particularly favored in this industry due to its ability to enhance the properties of materials used across various transportation methods.

Automative components

Ductile iron, produced with Magnesium Ferrosilicon, finds application in manufacturing automotive components such as crankshafts, valve stems, and suspension components. These parts benefit from the improved mechanical properties of ductile iron, resulting in stronger and more durable vehicles.

Railway components

In the railway industry, ductile iron produced with Magnesium Ferrosilicon is employed in the production of rail car parts like wheel hubs and suspension systems. The enhanced strength and ductility of this material contribute to the safety and reliability of rail transportation.

Ductile iron production

Magnesium Ferrosilicon serves as a spheroidizer in the production of ductile or nodular iron. This type of cast iron is renowned for its high strength and ductility, making it suitable for critical parts in the automotive and railway industries, such as engine shells, gearboxes, and rail car components.

Anti-corrosion coating

Coatings containing Magnesium Ferrosilicon are applied to ship components in the marine sector to increase their resistance to corrosion. This is vital for extending the lifespan and enhancing the reliability of ships.

Electrical systems

In electric vehicles (EVs) and hybrid vehicles, materials based on Magnesium Ferrosilicon may be used in electrical systems, contributing to the efficiency and performance of these vehicles.

Weight reduction

Magnesium Ferrosilicon is employed in the production of lightweight alloys, particularly relevant in the aerospace and automotive sectors. Lightweight materials aid in reducing overall vehicle weight, improving fuel efficiency, and minimizing environmental impact.

Ductile iron

Ductile iron is particularly useful in many automotive parts, where strength must exceed that of aluminum but steel is not necessarily required. Other important industrial applications include extra-urban diesel trucks, Class 8 trucks, agricultural tractors, and oil well pumps. Also, in wind turbines, spheroidal graphite cast iron is used for parts and saccharic hubs such as the turbine frame.

Microsilica

Microsilica powder plays a crucial role in enhancing the performance and lifespan of transportation infrastructure, offering numerous benefits to both travelers and the environment.

Reduction of environmental effects

The use of microsilica in concrete can lead to more sustainable transportation infrastructure. Its use enables the production of high-strength concrete with reduced cement content, which reduces carbon emissions associated with cement production.

High performance concrete

Microsilica serves as an additive in concrete mixes, enhancing its strength, durability, and wear resistance. This high-performance concrete is employed in constructing bridges, roads, tunnels, and other transportation infrastructure, resulting in longer-lasting and more reliable structures.

Permeability reduction

Microsilica aids in reducing the permeability of concrete, making it less susceptible to water penetration and corrosion of reinforcing steel. This is particularly crucial for transportation infrastructures exposed to harsh environmental conditions, such as bridges and coastal highways.

Increasing Durability

Transportation infrastructures benefit from the increased durability of concrete containing Microsilica, resulting in prolonged lifespan, reduced maintenance costs, and minimized disruptions to transportation networks.

Improved surface finish

Microsilica enhances the surface and workability of concrete, facilitating the creation of precise and smooth transportation infrastructure elements like road surfaces and bridge decks.

Increasing load bearing capacity

Addition of Microsilica to concrete enhances its load-bearing capacity, crucial for constructing transportation structures like highway overpasses and railway bridges required to withstand heavy traffic loads.