Flammability

No

Chemical Formula

MgFeSi

melting point

1210°C - 1380°C

دمای جوش

2355°C

Volumetric mass

2.4 to 5.1

Color

Dark Gray

12

Mg

Magnesium

24.310

14

Si

Silicon

28.086

13

Al

Aluminum

26.982

20

Ca

Calsium

40.078

26

Fe

Iron

55.840

What is Magnesium Ferrosilicon?

Magnesium Ferrosilicon (FeSiMg) is a ferroalloy comprised of Iron (Fe), Silicon (Si), Magnesium (Mg), and trace amounts of other metals. This material is widely used in metallurgical processes and alloy production due to its ability to introduce silicon and Magnesium elements into various alloys. One of its primary applications is in the production of ductile iron, where the addition of Magnesium Ferrosilicon to molten iron promotes the formation of graphite nodules. These nodules enhance the strength and toughness of cast iron by preventing crack propagation, thereby improving its mechanical properties.

Applications

Nucleating Agent and Mechanical Improvement of Cast Iron

Inoculant in Ductile Cast Iron Production

Alloying Agent in Cast Iron Parts

Laboratory Parameters

Ferrosilico Magnesium exhibits various physical and chemical properties. Some of these properties include:

- Melting Point: Varies from 1210°C to 1380°C depending on the silicon content and impurities.

- Boiling Point: Around 2355°C for all types of Magnesium Ferrosilicon.

- Color: Ranges from silver to dark gray.

- Odor:

- Solubility: Reacts with water, producing hydrogen gas.

- Combustibility: Dust particles are combustible.

- Volumetric Mass: Typically ranges from 2.4 g/cm³ to 5.1 g/cm³, proportional to the silicon content.

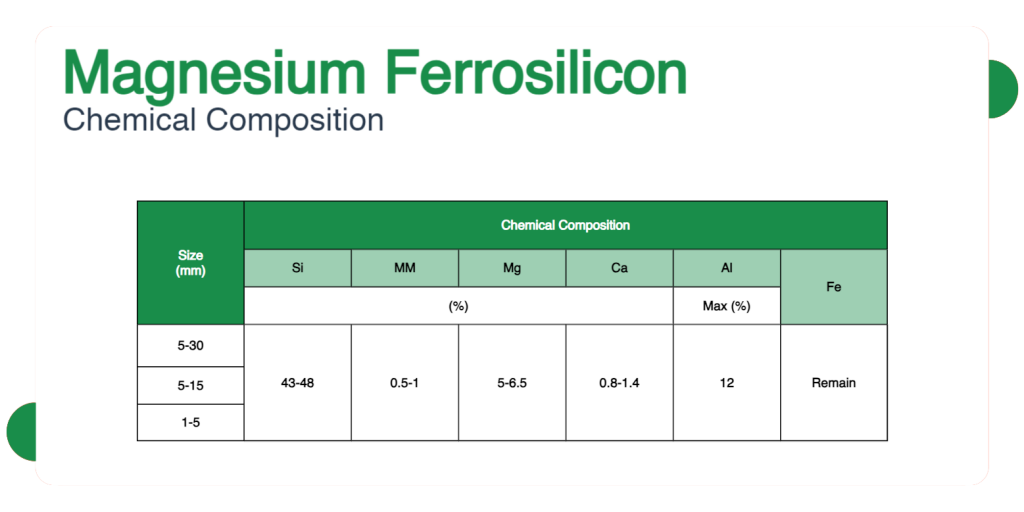

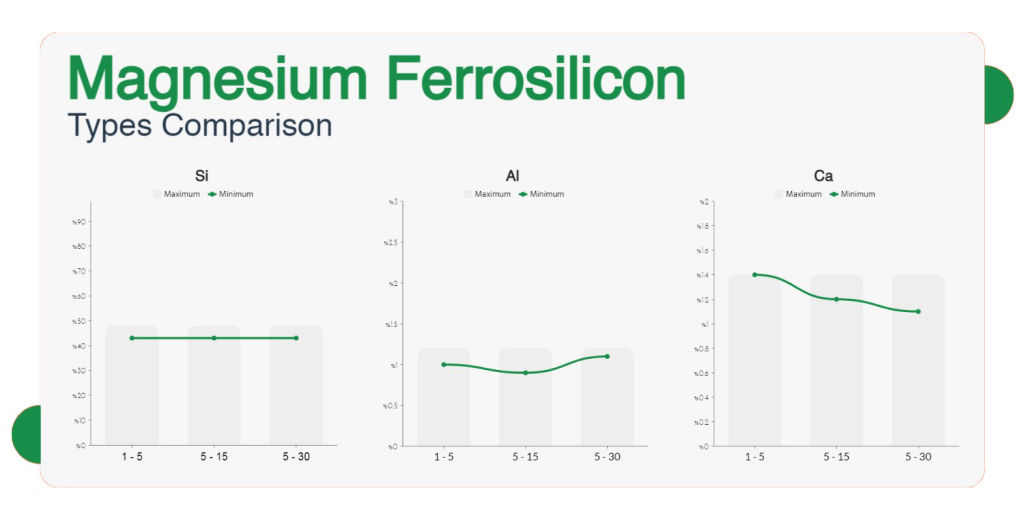

Granulation and Grades

Magnesium Ferrosilicon can be classified into different grain sizes, but the main characteristics remain consistent across all classes. This product, manufactured by Iran Ferrosilice, is available in three grain sizes: 1-5 mm, 5-15 mm, and 5-30 mm.

- Fine (1-5 mm)

- Medium (5-15 mm)

- Coarse (5-30 mm)

MgFeSi

Magnesium Ferrosilicon 15-30 mm

MgFeSi

Magnesium Ferrosilicon 5-15 mm

MgFeSi

Magnesium Ferrosilicon 1-5 mm

Packages

produced Ferrosilicon by Iran’s ferrosilicon factory can be sold in the following two ways based on the type of granularity, volume and customer demands:

- Barrel – 40 Kg

- Big Bag – 1000 Kg