No

SiO2

Vary

Vary

0.4 to 0.6

14 to 20

What is Ferrogel?

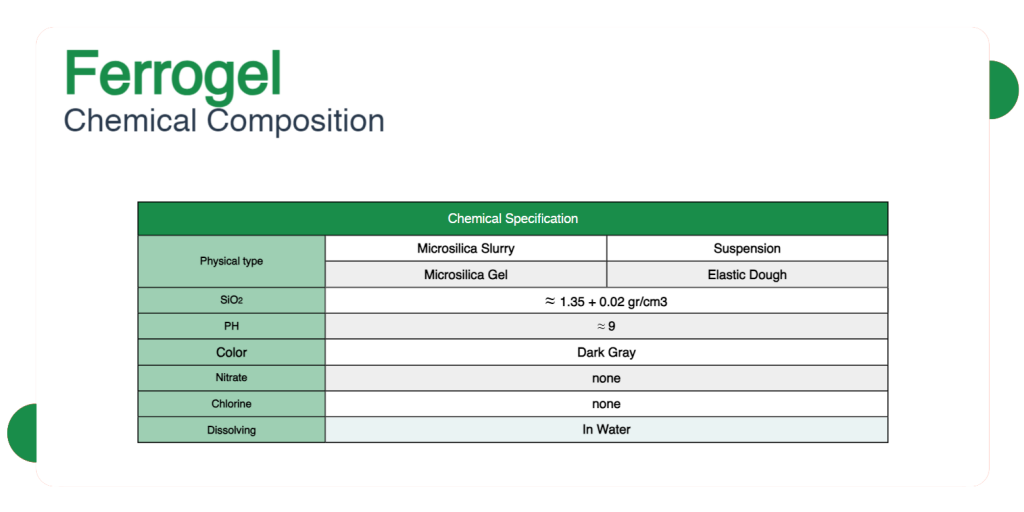

Ferrogel is an additive designed to enhance the quality, strength, reliability, and durability of concrete. Its key components include Microsilica powder, superplasticizer based on polycarboxylate ether, concrete fibers, and other additives for optimizing concrete performance based on the method of Microsilica gel production and the product class used. The Microsilica slurry product is a stable suspension of silica fume in water. Possessing pozzolanic properties, this product reacts with calcium hydroxide released during cement hydration. The resulting secondary products improve concrete sealing properties, impermeability, and mechanical and abrasion resistance.

Applications

Laboratory Parameters

Common physical and chemical properties of Microsilica include:

- Chemical Formula: Primarily composed of Silicon Dioxide (SiO2), comprising 85-97% of the mass. It also contains varying proportions of compounds such as Iron Oxide (Fe2O3), Aluminum Oxide (Al2O3), Calcium Oxide (CaO), Magnesium Oxide (MgO), among others.

- Specific Gravity: Ranges from 2.2 to 2.3 depending on density and purity.

- Melting Point: Variable based on application and physical properties.

- Boiling Point: Variable based on application and physical properties.

- Appearance and Color: Spherical particles with an average diameter of 40 micrometers, typically gray in color.

- Odor: Odorless

- Solubility: Insoluble in water.

- Combustibility: Non-combustible.

- Volumetric Mass (Density): Between 0.4 and 0.6 g/cm³.

- Specific Surface Area: Ranges from 14 to 20 square meters per gram.

Types and Grades

This product can be classified into different categories including Microsilica slurry and various types of Microsilica gels such as base gel, high slump gel, fibrous base gel, and high fibrous slump gel.

- Slurry

- Base

- Fiber Base

- High Slump

- High Fibrous Slump

Ferrogel

Slurry

Slurry (FS PR642)

Ferrogel

Base

Base FB SP110

Ferrogel

Fiber Base

Fiber Base FFB SP110

Ferrogel

High Slump

High Slump FSH R400

Ferrogel

Fibrous High Slump

Fibrous High Slump FFSH-400

Ferrogel

Slurry

Slurry (FS PR642)

Ferrogel

Base

Base (FB SP110)

Ferrogel

Fiber Base

Fiber Base (FFB SP110)

Ferrogel

High Slump

High Slump (FSH R400)

Ferrogel

Fibrous High Slump

Fibrous High Slump (FFSH-400)

Benefits of Using Ferrogel

- Reduction of segregation and water shedding of concrete, particularly in smooth concrete with high slump.

- Enhancement of concrete efficiency during execution operations, maintaining it throughout concreting.

- Reduction of the water-cement ratio across various concrete resistance categories.

- Decrease in concrete permeability against water and other aggressive substances.

- Increase in concrete durability against aggressive agents and corrosive environments.

- Improvement in mechanical resistance, including compressive, bending, and abrasion resistance, compared to normal concrete.

- Production of concrete containing ferrogel resistant to the penetration of destructive ions such as chlorides, sulfates, salts, hydroxides, and chemical solutions.

- Production of highly durable concrete containing ferrogel, suitable for marine and coastal structures.

- Production of highly durable concrete containing ferrogel, suitable for structures subjected to freezing and thawing cycles.

- Enhancement of concrete pumpability and reduction in the wear and tear of concreting equipment.

This product can be categorized into different types, including Microsilica slurry and various types of Microsilica gels such as base gel, high slump gel, fibrous base gel, and high fibrous slump gel.

Packages

Produced Microsilica by Iran’s ferrosilicon factory can be sold in the following two ways based on the type of granularity, volume and customer demands:

- Bucket – 40Kg

- Bag – 40 Kg